Thanks to GPS and wireless technology, Joe Runyan of Hangers Cleaners is “riding shotgun” whenever his drivers pick up a customer’s order.

About a year ago, Runyan installed a system that tracks the whereabouts of the dry cleaner’s six vans. He knows how fast his drivers are going, how hard they are braking and whether they’re idling too long. In fact, he can set parameters for any of those metrics. If a driver exceeds the boundaries, the system shoots an email alert to Runyan.

Even though he has a relatively small number of vans compared to UPS and other big companies, Runyan invested in fleet tracking

because his vehicles play an important role in the business. He estimates his drivers bring in about two-thirds of the clothing that Hangers cleans.

“It just got to the point where I wanted to have an idea of where they were and how they were driving,” Runyan said.

He didn’t think his drivers were doing anything wrong, but he wondered if he could find a way to make his fleet more

efficient. He even started quizzing UPS drivers whenever they came into his store to see how that company monitored its trucks.

Runyan ended up using Sprint’s Connected Fleet solution. Runyan is a former Sprint employee, and an old friend who still works there mentioned the program to him over lunch one day.

As part of Connected Fleet, Runyan hooked up a GPS-enabled Geotab GO6 device in each of his vans. The GO6 is about the size of a hockey puck, and it connects to each vehicle’s onboard diagnostic port. (The port is the plug that your mechanic uses to check your car’s computer; most vehicles made in the last 15 years have one.) The install time was 90 seconds for the first one, and even less for the others.

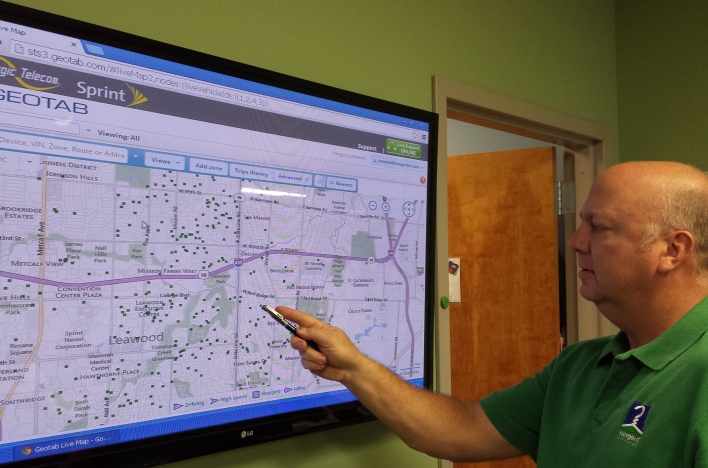

The system, which runs on Sprint’s network, provides data in real time. In fact, Runyan had a flat-screen monitor mounted in Hangers’ office, and it shows where the vans are at all times.

Individual drivers’ stats also are on display, so there is some good-natured ribbing about who’s driving better … or worse.

“Everybody sees it,” Runyan said. “You can’t walk in our office and not see that flat-screen.”

An Idle Threat

The tracking devices quickly uncovered a big problem. Runyan’s drivers were letting their vehicles run for 20 to 30 minutes each morning before they got on the road. As a result, he was able to warn them about excessive idling. Now, if a van is left running more than 10 minutes, the boss gets an email.

Runyan has saved between $8,000 and $10,000 simply on fuel costs. He believes the vans are suffering less wear and tear overall, though that’s harder to quantify.

The system also showed Runyan that one driver was consistently speeding and making other bad decisions behind the wheel. When a series of interventions didn’t take, Runyan had to let that person go.

What do the drivers think about the tracking system? For the first few weeks, Runyan didn’t tell them about the devices—he needed to get some baseline readings. Once the drivers found out, they didn’t appear to be upset or annoyed.

“It did not faze them a bit,” he said. “I think they were more curious about how it worked.”

A fleet-tracking solution might not be right for every business, but it’s been a boost for Hangers Cleaners.

“The simplicity of it has really shocked me,” Runyan said. “It surprises me that it’s not more prevalent.”